Contact

Address

No. 266 Tianshan Street, National High tech Development Zone, Shijiazhuang City, Hebei Province

Product Overview:

Vibrating fluidized bed is a type of airflow drying widely used in industries such as pharmaceuticals, chemicals, food, and building materials. For products such as sodium sulfate and potassium sulfate produced in the lithium salt industry, a vibrating fluidized bed dryer can be used.

View Details

View More

Vibrating fluidized bed is a type of airflow drying widely used in industries such as pharmaceuticals, chemicals, food, and building materials. For products such as sodium sulfate and potassium sulfate produced in the lithium salt industry, a vibrating fluidized bed dryer can be used.

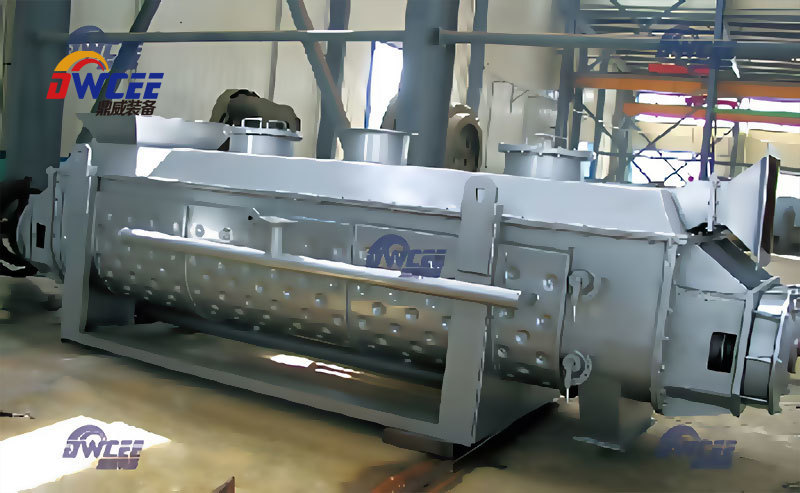

Product Overview:

The hollow paddle shaft rotates slowly under the drive of the transmission system. Materials enter the machine from the feed port and are conveyed to the discharge port through the hollow paddle shaft. Meanwhile, heat media such as steam, hot water or heat transfer oil are introduced into the hollow blades and the jacket, and the materials are dried through conduction heating.

View Details

View More

The hollow paddle shaft rotates slowly under the drive of the transmission system. Materials enter the machine from the feed port and are conveyed to the discharge port through the hollow paddle shaft. Meanwhile, heat media such as steam, hot water or heat transfer oil are introduced into the hollow blades and the jacket, and the materials are dried through conduction heating.

Applications:

Drying operations for new energy industries such as lithium chloride, lithium hydroxide, lithium carbonate, ternary materials and precursors, graphite, and positive and negative electrode materials.

View Details

View More

Drying operations for new energy industries such as lithium chloride, lithium hydroxide, lithium carbonate, ternary materials and precursors, graphite, and positive and negative electrode materials.

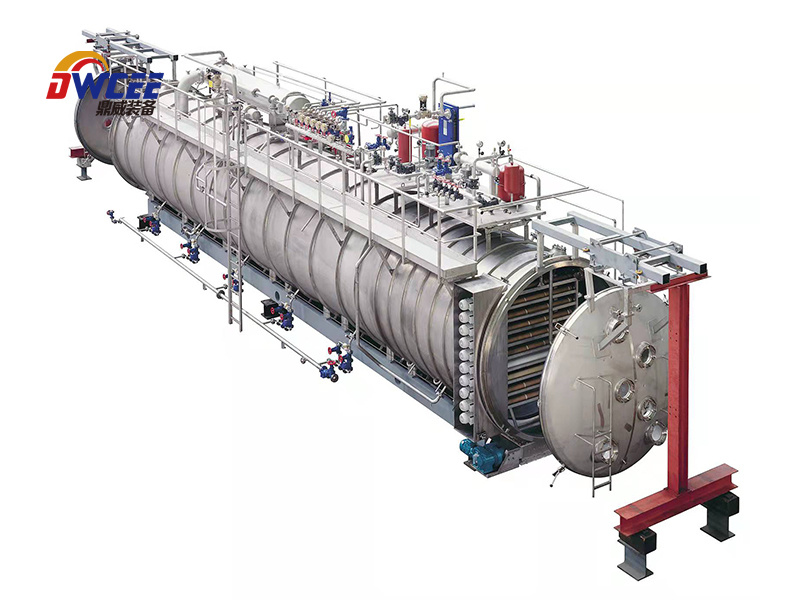

Product Overview:

The ME-VBD series low-temperature continuous vacuum belt dryer designed by our company can meet the drying requirements of high viscosity, high fat, high sugar, high heat sensitivity materials, and active materials that other drying equipment cannot solve due to its low-temperature vacuum drying.

View Details

View More

The ME-VBD series low-temperature continuous vacuum belt dryer designed by our company can meet the drying requirements of high viscosity, high fat, high sugar, high heat sensitivity materials, and active materials that other drying equipment cannot solve due to its low-temperature vacuum drying.

Product Overview:

The ME-VBD series low-temperature continuous vacuum belt dryer designed by our company can meet the drying requirements of high viscosity, high fat, high sugar, high heat sensitivity materials, and active materials that other drying equipment cannot solve due to its low-temperature vacuum drying.

View Details

View More

The ME-VBD series low-temperature continuous vacuum belt dryer designed by our company can meet the drying requirements of high viscosity, high fat, high sugar, high heat sensitivity materials, and active materials that other drying equipment cannot solve due to its low-temperature vacuum drying.

Spray drying in coal chemical industry

Product Overview:

The ME-VBD series low-temperature continuous vacuum belt dryer designed by our company can meet the drying requirements of high viscosity, high fat, high sugar, high heat sensitivity materials, and active materials that other drying equipment cannot solve due to its low-temperature vacuum drying.

View Details

View More

The ME-VBD series low-temperature continuous vacuum belt dryer designed by our company can meet the drying requirements of high viscosity, high fat, high sugar, high heat sensitivity materials, and active materials that other drying equipment cannot solve due to its low-temperature vacuum drying.

Applications

Drying operations for new energy industries such as lithium chloride, lithium hydroxide, lithium carbonate, ternary materials and precursors, graphite, and positive and negative electrode materials.

View Details

View More

Drying operations for new energy industries such as lithium chloride, lithium hydroxide, lithium carbonate, ternary materials and precursors, graphite, and positive and negative electrode materials.