- 产品描述

-

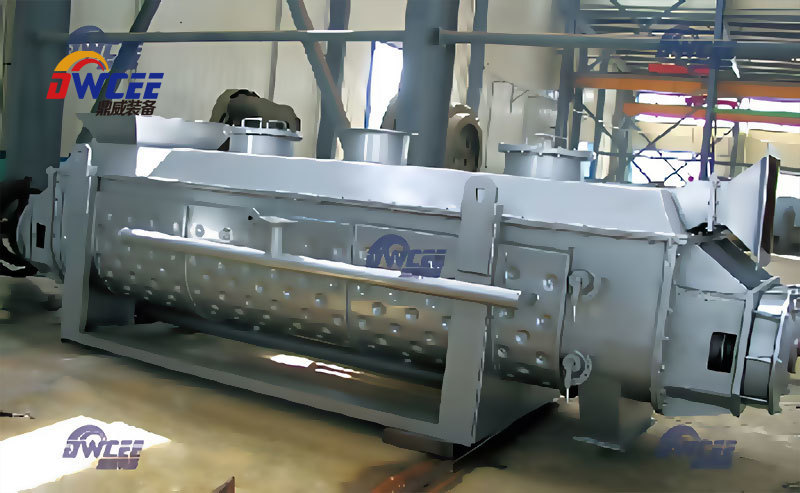

Vibrating fluidized bed is a drying technology developed in the 1960s and is currently widely applied in the chemical, light industry, pharmaceutical, food and building materials industries. Our company has collaborated with higher education institutions to develop vibrating fluidized bed drying (cooling, humidifying) machines. These machines feature an advanced structure, reliable quality and wide application range. It is now widely used in the pharmaceutical, chemical, food, building materials and other industries.

Working principle

This machine generates excitation force by the throwing of a vibration motor. Under the action of the excitation force in the given direction, the material jumps forward. Meanwhile, the hot air input from the bottom of the bed keeps the material in a fluidized state, allowing the material particles to fully contact with the hot air, thereby achieving the drying effect. The material enters from the feeding port. The material on the vibrating chute and the hot air introduced from the lower part of the chute come into orthogonal contact for heat transfer. The wet air is drawn out by the induced draft fan, and the dry material is discharged from the discharge port.

Vibrating fluidized bed Specification table

Model Fluidized bed area m² Overall dimensions mm Power of vibrating motor kw 3×0.3 0.9 3000×1350×1650 0.8×2 4.5×0.3 1.35 4500×1350×1650 0.8×2 4.5×0.45 2.025 4500×1550×1700 1.1×2 4.5×0.6 2.7 4500×1650×1700 1.1×2 6×0.45 2.7 6000×1650×1700 1.5×2 6×0.6 3.6 6000×1650×1700 1.5×2 6×0.75 4.5 6000×1850×1850 2.2×2 6×0.9 5.4 6000×2000×1850 2.2×2 7.5×0.6 4.5 7500×1850×1850 2.2×2 7.5×0.75 5.625 7500×2000×1850 3×2 7.5×0.9 6.75 7500×2100×1850 3×2 7.5×1.2 9 7500×2500×2050 3×2

Factory

Shijiazhuang Dingwei Chemical Equipment Engineering Co., Ltd. is a national high-tech enterprise that integrates engineering equipment research and development, design, production, installation, commissioning, and after-sales service.

The company is mainly committed to the supply of evaporation engineering, crystallization engineering, drying engineering, tower and distillation engineering systems. It is a leading technology provider and general contractor of process equipment and system engineering in China, with a second level professional contracting qualification for building electromechanical installation engineering, a second level general contracting qualification for petrochemical engineering construction, a D-level pressure vessel manufacturing qualification, and a GC2 industrial pipeline installation qualification.

Company Eexhibition

Qualification Certificate

Vibrated fluidized bed

Vibrating fluidized bed is a type of airflow drying widely used in industries such as pharmaceuticals, chemicals, food, and building materials. For products such as sodium sulfate and potassium sulfate produced in the lithium salt industry, a vibrating fluidized bed dryer can be used.

Share to

- 产品描述

-

Vibrating fluidized bed is a drying technology developed in the 1960s and is currently widely applied in the chemical, light industry, pharmaceutical, food and building materials industries. Our company has collaborated with higher education institutions to develop vibrating fluidized bed drying (cooling, humidifying) machines. These machines feature an advanced structure, reliable quality and wide application range. It is now widely used in the pharmaceutical, chemical, food, building materials and other industries.

Working principle

This machine generates excitation force by the throwing of a vibration motor. Under the action of the excitation force in the given direction, the material jumps forward. Meanwhile, the hot air input from the bottom of the bed keeps the material in a fluidized state, allowing the material particles to fully contact with the hot air, thereby achieving the drying effect. The material enters from the feeding port. The material on the vibrating chute and the hot air introduced from the lower part of the chute come into orthogonal contact for heat transfer. The wet air is drawn out by the induced draft fan, and the dry material is discharged from the discharge port.

Vibrating fluidized bed Specification table

Model Fluidized bed area m² Overall dimensions mm Power of vibrating motor kw 3×0.3 0.9 3000×1350×1650 0.8×2 4.5×0.3 1.35 4500×1350×1650 0.8×2 4.5×0.45 2.025 4500×1550×1700 1.1×2 4.5×0.6 2.7 4500×1650×1700 1.1×2 6×0.45 2.7 6000×1650×1700 1.5×2 6×0.6 3.6 6000×1650×1700 1.5×2 6×0.75 4.5 6000×1850×1850 2.2×2 6×0.9 5.4 6000×2000×1850 2.2×2 7.5×0.6 4.5 7500×1850×1850 2.2×2 7.5×0.75 5.625 7500×2000×1850 3×2 7.5×0.9 6.75 7500×2100×1850 3×2 7.5×1.2 9 7500×2500×2050 3×2

Factory

Shijiazhuang Dingwei Chemical Equipment Engineering Co., Ltd. is a national high-tech enterprise that integrates engineering equipment research and development, design, production, installation, commissioning, and after-sales service.

The company is mainly committed to the supply of evaporation engineering, crystallization engineering, drying engineering, tower and distillation engineering systems. It is a leading technology provider and general contractor of process equipment and system engineering in China, with a second level professional contracting qualification for building electromechanical installation engineering, a second level general contracting qualification for petrochemical engineering construction, a D-level pressure vessel manufacturing qualification, and a GC2 industrial pipeline installation qualification.

Company Eexhibition

Qualification Certificate

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.

Related Products

Vibrating fluidized bed is a type of airflow drying widely used in industries such as pharmaceuticals, chemicals, food, and building materials. For products such as sodium sulfate and potassium sulfate produced in the lithium salt industry, a vibrating fluidized bed dryer can be used.

The hollow paddle shaft rotates slowly under the drive of the transmission system. Materials enter the machine from the feed port and are conveyed to the discharge port through the hollow paddle shaft. Meanwhile, heat media such as steam, hot water or heat transfer oil are introduced into the hollow blades and the jacket, and the materials are dried through conduction heating.

(1) Continuous crystallization process and equipment for sodium sulfate decahydrate in battery recycling, lithium mica extraction, lithium pyroxene extraction, and salt lake lithium extraction processes;

(2) Continuous crystallization process and equipment for lithium iron phosphate raw material ammonium phosphate.

Evaporative crystallization is a common separation and purification method mainly used to separate solutes from solutions. The basic principle is to partially evaporate the solvent in the solution by heating or reducing pressure, thereby increasing the concentration of solute, and ultimately achieving solute saturation and crystallization.