- 产品描述

-

Product Overview

The VBD series of fully automatic vacuum low-temperature continuous belt dryers is a brand-new concept of highly efficient, energy-saving and environmentally friendly drying equipment. It can dry high-sugar, high-fat, high-viscosity, highly heat-sensitive materials and active materials under vacuum and low temperature. The continuous feeding and discharging under vacuum and the controllability of process operation parameters can effectively ensure the stability of product quality, transforming static drying into dynamic drying. This not only significantly increases output but also comprehensively reduces production energy consumption.

Main models

◆ Laboratory vacuum belt dryer:

Application fields: Food, pharmaceuticals, chemicals, and R&D departments and laboratories of universities, etc

Effective area :1m2 to 5m2

◆ Small vacuum belt dryer:

1-3 belts and 4-5 heating zones, the components of these devices are applied to the test equipment of medium and large vacuum belt dryers.

Effective area :1m2 to 20m2

◆ Large and medium-sized vacuum belt dryers:

With 4 to 10 heating zones and 4 to 6 heating areas, this ideal device for continuous and fully automatic production features an automatic CIP cleaning process, enabling the equipment to be quickly cleaned within a short period of time and meeting GMP production requirements.

Effective area :30m2 to 200m2

Factory

Shijiazhuang Dingwei Chemical Equipment Engineering Co., Ltd. is a national high-tech enterprise that integrates engineering equipment research and development, design, production, installation, commissioning, and after-sales service.

The company is mainly committed to the supply of evaporation engineering, crystallization engineering, drying engineering, tower and distillation engineering systems. It is a leading technology provider and general contractor of process equipment and system engineering in China, with a second level professional contracting qualification for building electromechanical installation engineering, a second level general contracting qualification for petrochemical engineering construction, a D-level pressure vessel manufacturing qualification, and a GC2 industrial pipeline installation qualification.

Company Eexhibition

Qualification Certificate

Vacuum belt dryer

The ME-VBD series low-temperature continuous vacuum belt dryer designed by our company can meet the drying requirements of high viscosity, high fat, high sugar, high heat sensitivity materials, and active materials that other drying equipment cannot solve due to its low-temperature vacuum drying.

Share to

- 产品描述

-

Product Overview

The VBD series of fully automatic vacuum low-temperature continuous belt dryers is a brand-new concept of highly efficient, energy-saving and environmentally friendly drying equipment. It can dry high-sugar, high-fat, high-viscosity, highly heat-sensitive materials and active materials under vacuum and low temperature. The continuous feeding and discharging under vacuum and the controllability of process operation parameters can effectively ensure the stability of product quality, transforming static drying into dynamic drying. This not only significantly increases output but also comprehensively reduces production energy consumption.

Main models

◆ Laboratory vacuum belt dryer:

Application fields: Food, pharmaceuticals, chemicals, and R&D departments and laboratories of universities, etc

Effective area :1m2 to 5m2

◆ Small vacuum belt dryer:

1-3 belts and 4-5 heating zones, the components of these devices are applied to the test equipment of medium and large vacuum belt dryers.

Effective area :1m2 to 20m2

◆ Large and medium-sized vacuum belt dryers:

With 4 to 10 heating zones and 4 to 6 heating areas, this ideal device for continuous and fully automatic production features an automatic CIP cleaning process, enabling the equipment to be quickly cleaned within a short period of time and meeting GMP production requirements.

Effective area :30m2 to 200m2

Factory

Shijiazhuang Dingwei Chemical Equipment Engineering Co., Ltd. is a national high-tech enterprise that integrates engineering equipment research and development, design, production, installation, commissioning, and after-sales service.

The company is mainly committed to the supply of evaporation engineering, crystallization engineering, drying engineering, tower and distillation engineering systems. It is a leading technology provider and general contractor of process equipment and system engineering in China, with a second level professional contracting qualification for building electromechanical installation engineering, a second level general contracting qualification for petrochemical engineering construction, a D-level pressure vessel manufacturing qualification, and a GC2 industrial pipeline installation qualification.

Company Eexhibition

Qualification Certificate

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.

Related Products

Vibrating fluidized bed is a type of airflow drying widely used in industries such as pharmaceuticals, chemicals, food, and building materials. For products such as sodium sulfate and potassium sulfate produced in the lithium salt industry, a vibrating fluidized bed dryer can be used.

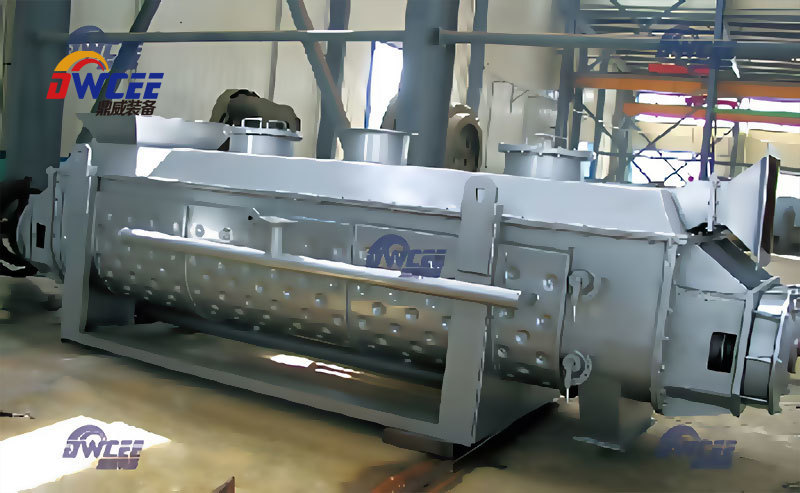

The hollow paddle shaft rotates slowly under the drive of the transmission system. Materials enter the machine from the feed port and are conveyed to the discharge port through the hollow paddle shaft. Meanwhile, heat media such as steam, hot water or heat transfer oil are introduced into the hollow blades and the jacket, and the materials are dried through conduction heating.

(1) Continuous crystallization process and equipment for sodium sulfate decahydrate in battery recycling, lithium mica extraction, lithium pyroxene extraction, and salt lake lithium extraction processes;

(2) Continuous crystallization process and equipment for lithium iron phosphate raw material ammonium phosphate.

Evaporative crystallization is a common separation and purification method mainly used to separate solutes from solutions. The basic principle is to partially evaporate the solvent in the solution by heating or reducing pressure, thereby increasing the concentration of solute, and ultimately achieving solute saturation and crystallization.