- 产品描述

-

Product Overview

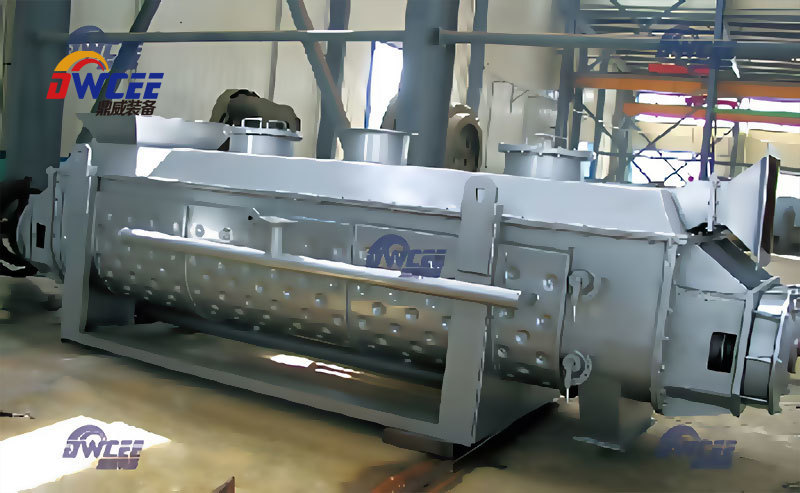

The disc continuous dryer is a new type of conduction drying equipment, featuring continuous operation, closed operation, high evaporation intensity, reasonable humidity gradient distribution, low power consumption and small floor space.

Meanwhile, its configuration is simple and does not require the necessary dust post-treatment equipment such as cyclone dust collectors and bag filters for air-flow dryers. It does not use hot air as the heating medium, so there will be no product loss caused by poor separation of hot air and dust being carried along with the exhaust gas.

The disc continuous dryer is composed of a drying disc, a rake arm, several rake blades installed on the rake arm, a main shaft, a rotating device, a casing, etc. Hot water is introduced into one end of the hollow drying disc and discharged from the other end for recycling.

The drying discs are divided into large discs and small discs, which are arranged horizontally in layers inside the dryer. The drying discs remain stationary. Under the action of the movement of the rake leaves, the materials on the large discs move from the outside to the inside and fall from the inner edge of the large discs to the inner edge of the small discs. The materials on the small discs move from the inside to the outside and fall from the outer edge of the small discs to the large discs The material is conveyed and turned on the surface of the drying disc by the rake blades, moving in an Archimedean spiral trajectory. During the movement, it is heated by the drying disc, and heat and mass transfer are carried out to complete the drying operation. The number of drying disc layers (drying area) is determined according to the output, properties, initial and final moisture content of the material to be dried.

The disc dryer operates vertically. Wet materials are added through the feeding port at the top and then discharged from the bottom of the dryer after passing through each layer of drying discs. The entire drying process is carried out in a closed manner. The moisture released from the materials is directly discharged into the atmosphere through the tail gas pipe at the top of the dryer. The main component of this tail gas is water vapor, which does not carry the dried products and will not cause pollution to the environment.

Disc dryer specification sheet

Specification Outer diameter(mm) Height(mm) Drying area(m²) Power(KW) φ1200-4 φ1850 2718 3.3 1.1 φ1200-6 φ1850 3138 4.9 φ1200-8 φ1850 3558 6.6 1.5 φ1200-10 φ1850 3978 8.2 φ1200-12 φ1850 4398 9.9 2.2 φ1500-6 φ2100 3022 8 2.2 φ1500-8 φ2100 3442 10.7 φ1500-10 φ2100 3862 13.4 3 φ1500-12 φ2100 4282 16.1 φ1500-14 φ2100 4702 18.8 φ1500-16 φ2100 5122 21.5 φ2200-6 φ2820 3793 18.5 φ2200-8 φ2820 4253 24.6 4 φ2200-10 φ2820 4713 30.8 φ2200-12 φ2820 5173 36.9 φ2200-14 φ2820 5633 43.1 5.5 φ2200-16 φ2820 6093 49.3 φ2200-18 φ2820 6553 55.4 7.5 φ2200-20 φ2820 7013 61.6 φ2500-6 φ3115 4070 26.3 4 φ2500-8 φ3115 4530 35 φ2500-10 φ3115 4990 43.8 5.5 φ2500-12 φ3115 5450 52.6 φ2500-14 φ3115 5910 61.3 7.5 φ2500-16 φ3115 6370 70.1 φ2500-18 φ3115 6830 78.9 11 φ2500-20 φ3115 7290 87.7 φ3000-6 φ3768 4580 36 5.5 φ300-8 φ3768 5080 48 7.5 φ3000-10 φ3768 5580 60 11 φ3000-12 φ3768 6080 72 φ3000-14 φ3768 6580 84 φ3000-16 φ3768 7080 96 φ3000-18 φ3768 7580 108 15 φ3000-20 φ3768 8230 120 18.5 φ3000-22 φ3768 8880 132 22 φ3000-24 φ3768 9530 144 30 φ3200-6 φ3968 4580 39.6 5.5 φ3200-8 φ3968 5080 52.8 7.5 φ3200-10 φ3968 5580 66 11 φ3200-12 φ3968 6080 79.2 φ3200-14 φ3968 6580 92.4 φ3200-16 φ3968 7080 105.6 φ3200-18 φ3968 7580 118.8 15 φ3200-20 φ3968 8230 132 18.5 φ3200-22 φ3968 8880 145.2 22 φ3200-24 φ3968 9530 158.4 30

Factory

Shijiazhuang Dingwei Chemical Equipment Engineering Co., Ltd. is a national high-tech enterprise that integrates engineering equipment research and development, design, production, installation, commissioning, and after-sales service.

The company is mainly committed to the supply of evaporation engineering, crystallization engineering, drying engineering, tower and distillation engineering systems. It is a leading technology provider and general contractor of process equipment and system engineering in China, with a second level professional contracting qualification for building electromechanical installation engineering, a second level general contracting qualification for petrochemical engineering construction, a D-level pressure vessel manufacturing qualification, and a GC2 industrial pipeline installation qualification.

Company Eexhibition

Qualification Certificate

Disc continuous dryer

Drying operations for new energy industries such as lithium chloride, lithium hydroxide, lithium carbonate, ternary materials and precursors, graphite, and positive and negative electrode materials.

Share to

- 产品描述

-

Product Overview

The disc continuous dryer is a new type of conduction drying equipment, featuring continuous operation, closed operation, high evaporation intensity, reasonable humidity gradient distribution, low power consumption and small floor space.

Meanwhile, its configuration is simple and does not require the necessary dust post-treatment equipment such as cyclone dust collectors and bag filters for air-flow dryers. It does not use hot air as the heating medium, so there will be no product loss caused by poor separation of hot air and dust being carried along with the exhaust gas.

The disc continuous dryer is composed of a drying disc, a rake arm, several rake blades installed on the rake arm, a main shaft, a rotating device, a casing, etc. Hot water is introduced into one end of the hollow drying disc and discharged from the other end for recycling.

The drying discs are divided into large discs and small discs, which are arranged horizontally in layers inside the dryer. The drying discs remain stationary. Under the action of the movement of the rake leaves, the materials on the large discs move from the outside to the inside and fall from the inner edge of the large discs to the inner edge of the small discs. The materials on the small discs move from the inside to the outside and fall from the outer edge of the small discs to the large discs The material is conveyed and turned on the surface of the drying disc by the rake blades, moving in an Archimedean spiral trajectory. During the movement, it is heated by the drying disc, and heat and mass transfer are carried out to complete the drying operation. The number of drying disc layers (drying area) is determined according to the output, properties, initial and final moisture content of the material to be dried.

The disc dryer operates vertically. Wet materials are added through the feeding port at the top and then discharged from the bottom of the dryer after passing through each layer of drying discs. The entire drying process is carried out in a closed manner. The moisture released from the materials is directly discharged into the atmosphere through the tail gas pipe at the top of the dryer. The main component of this tail gas is water vapor, which does not carry the dried products and will not cause pollution to the environment.

Disc dryer specification sheet

Specification Outer diameter(mm) Height(mm) Drying area(m²) Power(KW) φ1200-4 φ1850 2718 3.3 1.1 φ1200-6 φ1850 3138 4.9 φ1200-8 φ1850 3558 6.6 1.5 φ1200-10 φ1850 3978 8.2 φ1200-12 φ1850 4398 9.9 2.2 φ1500-6 φ2100 3022 8 2.2 φ1500-8 φ2100 3442 10.7 φ1500-10 φ2100 3862 13.4 3 φ1500-12 φ2100 4282 16.1 φ1500-14 φ2100 4702 18.8 φ1500-16 φ2100 5122 21.5 φ2200-6 φ2820 3793 18.5 φ2200-8 φ2820 4253 24.6 4 φ2200-10 φ2820 4713 30.8 φ2200-12 φ2820 5173 36.9 φ2200-14 φ2820 5633 43.1 5.5 φ2200-16 φ2820 6093 49.3 φ2200-18 φ2820 6553 55.4 7.5 φ2200-20 φ2820 7013 61.6 φ2500-6 φ3115 4070 26.3 4 φ2500-8 φ3115 4530 35 φ2500-10 φ3115 4990 43.8 5.5 φ2500-12 φ3115 5450 52.6 φ2500-14 φ3115 5910 61.3 7.5 φ2500-16 φ3115 6370 70.1 φ2500-18 φ3115 6830 78.9 11 φ2500-20 φ3115 7290 87.7 φ3000-6 φ3768 4580 36 5.5 φ300-8 φ3768 5080 48 7.5 φ3000-10 φ3768 5580 60 11 φ3000-12 φ3768 6080 72 φ3000-14 φ3768 6580 84 φ3000-16 φ3768 7080 96 φ3000-18 φ3768 7580 108 15 φ3000-20 φ3768 8230 120 18.5 φ3000-22 φ3768 8880 132 22 φ3000-24 φ3768 9530 144 30 φ3200-6 φ3968 4580 39.6 5.5 φ3200-8 φ3968 5080 52.8 7.5 φ3200-10 φ3968 5580 66 11 φ3200-12 φ3968 6080 79.2 φ3200-14 φ3968 6580 92.4 φ3200-16 φ3968 7080 105.6 φ3200-18 φ3968 7580 118.8 15 φ3200-20 φ3968 8230 132 18.5 φ3200-22 φ3968 8880 145.2 22 φ3200-24 φ3968 9530 158.4 30

Factory

Shijiazhuang Dingwei Chemical Equipment Engineering Co., Ltd. is a national high-tech enterprise that integrates engineering equipment research and development, design, production, installation, commissioning, and after-sales service.

The company is mainly committed to the supply of evaporation engineering, crystallization engineering, drying engineering, tower and distillation engineering systems. It is a leading technology provider and general contractor of process equipment and system engineering in China, with a second level professional contracting qualification for building electromechanical installation engineering, a second level general contracting qualification for petrochemical engineering construction, a D-level pressure vessel manufacturing qualification, and a GC2 industrial pipeline installation qualification.

Company Eexhibition

Qualification Certificate

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.

Related Products

Vibrating fluidized bed is a type of airflow drying widely used in industries such as pharmaceuticals, chemicals, food, and building materials. For products such as sodium sulfate and potassium sulfate produced in the lithium salt industry, a vibrating fluidized bed dryer can be used.

The hollow paddle shaft rotates slowly under the drive of the transmission system. Materials enter the machine from the feed port and are conveyed to the discharge port through the hollow paddle shaft. Meanwhile, heat media such as steam, hot water or heat transfer oil are introduced into the hollow blades and the jacket, and the materials are dried through conduction heating.

(1) Continuous crystallization process and equipment for sodium sulfate decahydrate in battery recycling, lithium mica extraction, lithium pyroxene extraction, and salt lake lithium extraction processes;

(2) Continuous crystallization process and equipment for lithium iron phosphate raw material ammonium phosphate.

Evaporative crystallization is a common separation and purification method mainly used to separate solutes from solutions. The basic principle is to partially evaporate the solvent in the solution by heating or reducing pressure, thereby increasing the concentration of solute, and ultimately achieving solute saturation and crystallization.