- 产品描述

-

Product Introduction

New technologies and equipment for acid production from sulfur foam and desulfurization waste liquid

Scope of undertaking: EPC general contracting for acid production; Upgrading and transformation of wet, semi-dry and dry acid production processes

Technical features

① Short process, superior performance and small floor space occupied by the equipment.

② No odor, no new waste, and no secondary pollution.

③ The device is advanced and mature, with a high degree of automation, continuous and stable operation, and convenient operation.

④ Sulfur foam does not require drying or coal powder extraction, does not consume gas, and does not need oxygen-enriched combustion, saving 20-30% of energy consumption.

⑤ he production of trace amounts of dilute acid has solved the technical problem of dilute acid treatment in the process of acid production from desulfurization waste liquid, without affecting the ammonium sulfate production process and product quality.

⑥ It has wide applicability and is suitable for various horizontal and vertical furnaces in China.

⑦ Ensure that the desulfurization system for chemical products does not swell.

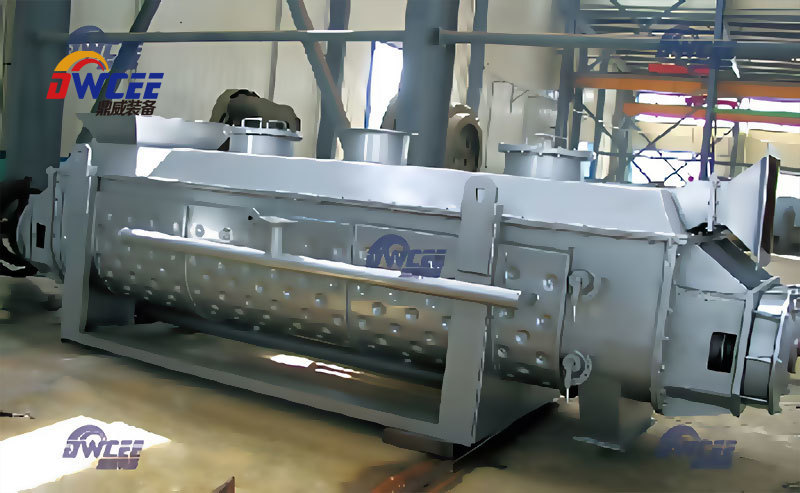

◆ Special equipment for drying ammonium sulfate in the coking industry

◆ Specialized disc drying equipment for coal moisture adjustment in the coking industry

◆ Zero discharge technology for coking wastewater

Factory

Shijiazhuang Dingwei Chemical Equipment Engineering Co., Ltd. is a national high-tech enterprise that integrates engineering equipment research and development, design, production, installation, commissioning, and after-sales service.

The company is mainly committed to the supply of evaporation engineering, crystallization engineering, drying engineering, tower and distillation engineering systems. It is a leading technology provider and general contractor of process equipment and system engineering in China, with a second level professional contracting qualification for building electromechanical installation engineering, a second level general contracting qualification for petrochemical engineering construction, a D-level pressure vessel manufacturing qualification, and a GC2 industrial pipeline installation qualification.

Company Eexhibition

Qualification Certificate

Sulfur foam two-phase acid production technology and EPC general contracting

Keywords:

Share to

- 产品描述

-

Product Introduction

New technologies and equipment for acid production from sulfur foam and desulfurization waste liquid

Scope of undertaking: EPC general contracting for acid production; Upgrading and transformation of wet, semi-dry and dry acid production processes

Technical features

① Short process, superior performance and small floor space occupied by the equipment.

② No odor, no new waste, and no secondary pollution.

③ The device is advanced and mature, with a high degree of automation, continuous and stable operation, and convenient operation.

④ Sulfur foam does not require drying or coal powder extraction, does not consume gas, and does not need oxygen-enriched combustion, saving 20-30% of energy consumption.

⑤ he production of trace amounts of dilute acid has solved the technical problem of dilute acid treatment in the process of acid production from desulfurization waste liquid, without affecting the ammonium sulfate production process and product quality.

⑥ It has wide applicability and is suitable for various horizontal and vertical furnaces in China.

⑦ Ensure that the desulfurization system for chemical products does not swell.

◆ Special equipment for drying ammonium sulfate in the coking industry

◆ Specialized disc drying equipment for coal moisture adjustment in the coking industry

◆ Zero discharge technology for coking wastewater

Factory

Shijiazhuang Dingwei Chemical Equipment Engineering Co., Ltd. is a national high-tech enterprise that integrates engineering equipment research and development, design, production, installation, commissioning, and after-sales service.

The company is mainly committed to the supply of evaporation engineering, crystallization engineering, drying engineering, tower and distillation engineering systems. It is a leading technology provider and general contractor of process equipment and system engineering in China, with a second level professional contracting qualification for building electromechanical installation engineering, a second level general contracting qualification for petrochemical engineering construction, a D-level pressure vessel manufacturing qualification, and a GC2 industrial pipeline installation qualification.

Company Eexhibition

Qualification Certificate

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.

Related Products

Vibrating fluidized bed is a type of airflow drying widely used in industries such as pharmaceuticals, chemicals, food, and building materials. For products such as sodium sulfate and potassium sulfate produced in the lithium salt industry, a vibrating fluidized bed dryer can be used.

The hollow paddle shaft rotates slowly under the drive of the transmission system. Materials enter the machine from the feed port and are conveyed to the discharge port through the hollow paddle shaft. Meanwhile, heat media such as steam, hot water or heat transfer oil are introduced into the hollow blades and the jacket, and the materials are dried through conduction heating.

(1) Continuous crystallization process and equipment for sodium sulfate decahydrate in battery recycling, lithium mica extraction, lithium pyroxene extraction, and salt lake lithium extraction processes;

(2) Continuous crystallization process and equipment for lithium iron phosphate raw material ammonium phosphate.

Evaporative crystallization is a common separation and purification method mainly used to separate solutes from solutions. The basic principle is to partially evaporate the solvent in the solution by heating or reducing pressure, thereby increasing the concentration of solute, and ultimately achieving solute saturation and crystallization.